Page 1144 - S.I.T.E.切削工具ガイドブックVol.4 鉄鋼・難削材料用

P. 1144

υ

Ϧ

ϧ ࡾඛཱπʔϧ

%3*--4

8)43 "5)

43Ճ༻ߗυϦϧ %λΠϓ

ߗυϦϧ $BSCJEF %SJMM GPS 43 NBDIJOJOH % 5ZQF

$"3#*%& %3*--4

ϋΠευϦϧ

)44 %3*--4 ɹ

֎෦څ༉

&95&3/"- 3&'6&-*/(

෦څ༉

*/5&3/"- $00-"/5 4611-:

ετϨʔτγϟϯΫ

453"*()5 4)"/,

ςʔύγϟϯΫ ۚܕͷྫྷ٫݀ʹ͓͚ΔԠྗ৯ׂΕΛ੍

5"1&3 4)"/, 4VQQSFTTJPO PG TUSFTT DPSSPTJPO DSBDLJOH JO UIF DPPMJOH IPMF PG UIF NPME

ϔουަࣜ

)&"% &9$)"/(& 5:1&

ελϯμʔυ ެࠩ NN 5PMFSBODF

45"/%"3% ܘ γϟϯΫ

ߴਫ਼Ճ͚ I I

)*() 13&$*4*0/

ઌϑϥοτ

'-"5 ୯Ґʢੇ๏ NNʣʗ6OJUʢ4J[F NNʣ

ҐஔܾΊ

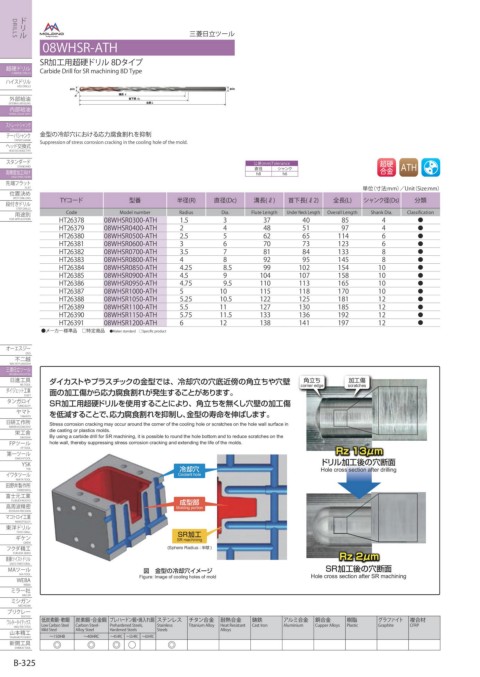

4105 %3*--*/( 5:ίʔυ ܕ൪ ܘ 3 ܘ %D ߔ Ὑ टԼ Ὑ શ - γϟϯΫܘ %T ྨ

ஈ͖υϦϧ

45&1 %3*--4

༻్ผ $PEF .PEFM OVNCFS 3BEJVT %JB 'MVUF -FOHUI 6OEFS /FDL -FOHUI 0WFSBMM -FOHUI 4IBOL %JB $MBTTJGJDBUJPO

'03 "11-*$"5*0/ )5 8)43 "5) ˔

)5 8)43 "5) ˔

)5 8)43 "5) ˔

)5 8)43 "5) ˔

)5 8)43 "5) ˔

)5 8)43 "5) ˔

)5 8)43 "5) ˔

)5 8)43 "5) ˔

)5 8)43 "5) ˔

)5 8)43 "5) ˔

)5 8)43 "5) ˔

)5 8)43 "5) ˔

)5 8)43 "5) ˔

)5 8)43 "5) ˔

˔ϝʔΧʔඪ४ɹ˘ಛఆɹ˔.BLFS TUBOEBSEɹ˘4QFDJGJD QSPEVDU

ΦʔΤεδʔ

04(

ෆೋӽ

/"$)* '6+*,04)*

ࡾඛཱπʔϧࡾඛཱπʔϧ

.*546#*4)* )*5"$)* 500-"$)* 500-

.*546#*4)* )*5

ਐ۩ μΠΧετϓϥενοΫͷۚܕͰɺྫྷ٫݀ͷ݀ఈۙͷཱ֯ͪ݀น ཱ֯ͪ Ճই

/4 500- corner edge scratches

μΠδΣοτۀ ໘ͷՃই͔ΒԠྗ৯ׂΕ͕ൃੜ͢Δ͜ͱ͕͋Γ·͢ɻ

%*+&5

λϯΨϩΠ 43Ճ༻ߗυϦϧΛ༻͢Δ͜ͱʹΑΓɺཱ֯ͪΛແ݀͘͠นͷՃই

56/("-0:

ϠϚτ Λݮ͢Δ͜ͱͰɺԠྗ৯ׂΕΛ੍͠ɺۚܕͷण໋Λ৳͠·͢ɻ

:"."50

ݚ࡞ॴ Stress corrosion cracking may occur around the corner of the cooling hole or scratches on the hole wall surface in

/*,,&/ ,04",64)0 die casting or plastics molds.

ӫࣷ By using a carbide drill for SR machining, it is possible to round the hole bottom and to reduce scratches on the

&*,04)"

'1πʔϧ hole wall, thereby suppressing stress corrosion cracking and extending the life of the molds.

3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3[

'1 500- 3[ ЖN[[[[[[[[ ЖЖЖЖЖЖЖЖЖЖЖЖЖЖЖЖЖЖЖЖЖЖЖЖЖЖNNNNNNNNNNNNN ЖN

ୈҰπʔϧ

υϦϧՃޙͷ݀அ໘ϦϧՃޙͷ݀அՃޙͷ

%"**$)* 500- υ ໘

:4,

:4, ྫྷ٫݀ H Hole cross section after drillingole crosss section aftf er drilling

Πϫλπʔϧ Coolant hole

*8"5" 500-

ాҪ࡞ॴ

5"/0* .'(

࢜ݩۀ

'6+*(&/ ,0(:0 ܕ෦

ߴपਫ਼ີ Molding portion

,04)6)" 13&$*4*0/

ϚίτϩΠۀ

.",050-0:

౦༸υϦϧ

50:0 %3*-- 43Ճ

Ϊέϯ SR machining

(*,&/

ϑΫμਫ਼ 4QIFSF 3BEJVT ٿ

3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3 3[

'6,6%" 4&*,0 3[ ЖN[[[[[[[[[[[[[[[[[[[[ ЖЖЖЖЖЖЖЖЖЖЖЖЖЖЖЖЖЖЖЖЖЖЖЖЖЖЖNNNNNNNNNNNNNNNЖN

ࡈ౻πΠετυϦϧ

4"*50 58*45 %3*--

."πʔϧ ਤɹۚܕͷྫྷ٫݀Πϝʔδ 43Ճޙͷ݀அ໘

." 500- Figure: Image of cooling holes of mold Hole cross section after SR machining

8&#"

8&#"

ϛϥʔࣾ

.*--&3

ϛγΨϯ

.*$)*("/

ϒϦΫϨʔ

#-*$,-&

ϫϧλʔλΠςοΫε ૉ߯ŋೈ߯ ૉ߯ŋ߹ۚ߯ ϓϨϋʔυϯ߯ɾমೖΕ߯ εςϯϨε νλϯ߹ۚ ߹ۚ ரమ Ξϧϛ߹ۚ ಔ߹ۚ थࢷ άϥϑΝΠτ ෳ߹ࡐ

8"-5&3 5*5&9 -PX $BSCPO 4UFFM $BSCPO 4UFFM 1SFIBSEFOFE 4UFFMT 4UBJOMFTT 5JUBOJVN "MMPZ )FBU 3FTJTUBOU $BTU *SPO "MVNJOJVN $VQQFS "MMPZT 1MBTUJD (SBQIJUF $'31

ࢁຊਫ਼ .JME 4UFFM "MMPZ 4UFFM )BSEFOFE 4UFFMT 4UFFMT "MMPZT

:".".050 4&*,0 ʙ )# ʙ )3$ ʙ )3$ ʙ )3$ ʙ )3$

৽։۩ ˕ ˕ ˕ ˓ ˕

4)*/,"* 500-

B-325