Page 1396 - S.I.T.E.切削工具ガイドブックVol.4 非鉄金属用

P. 1396

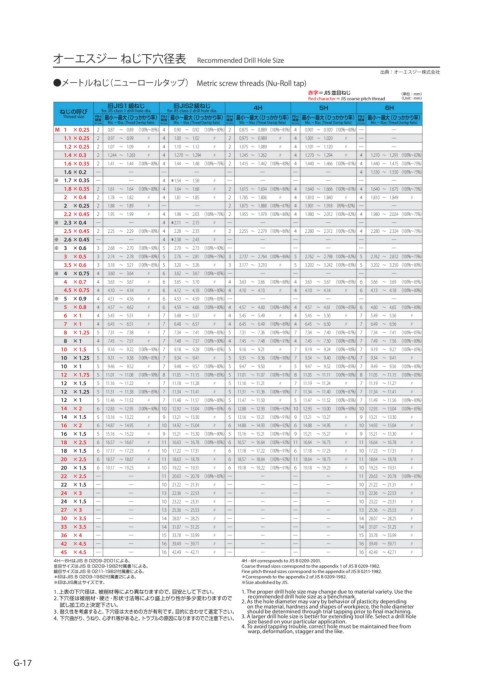

ΦʔΤεδʔ Ͷ͡Լ݀ܘදɹ3FDPNNFOEFE %SJMM )PMF 4J[F

ΦʔΤεδʔ Ͷ͡Լ݀ܘද

3FDPNNFOEFE %SJMM )PMF 4J[F

ग़యɿΦʔΤεδʔגࣜձࣾ

ग़యɿΦʔΤεδʔגࣜձࣾ

˔ϝʔτϧͶ͡ʢχϡʔϩʔϧλοϓʣɹ.FUSJD TDSFX UISFBET /V 3PMM UBQ

ࣈʹJISฒͶ͡ ʢ୯Ґɿmmʣ

ϝʔτϧͶ͡ʢχϡʔϩʔϧλοϓʣ Metric screw threads (Nu-Roll tap) Red characterʹJIS coarse pitch thread ʢUnitɿmmʣ

چ+*4 ڃͶ͡ چ+*4 ڃͶ͡ ) ) )

Ͷ͡ͷݺͼ for JIS class 1 drill hole dia. for JIS class 2 drill hole dia.

Thread size ਫ਼ ࠷খʙ࠷େʢͻ͔͔ͬΓʣ ਫ਼ ࠷খʙ࠷େʢͻ͔͔ͬΓʣ ਫ਼ ࠷খʙ࠷େʢͻ͔͔ͬΓʣ ਫ਼ ࠷খʙ࠷େʢͻ͔͔ͬΓʣ ਫ਼ ࠷খʙ࠷େʢͻ͔͔ͬΓʣ

3)

3)

3)

3)

3)

RH Limits Min. ʙ Max. (Thread Overlap Ratio) RH Limits Min. ʙ Max. (Thread Overlap Ratio) RH Limits Min. ʙ Max. (Thread Overlap Ratio) RH Limits Min. ʙ Max. (Thread Overlap Ratio) RH Limits Min. ʙ Max. (Thread Overlap Ratio)

M 1 ʷ 0.25 2 0.87 ʙ 0.89 ʢ100ˋʙ85ˋʣ 4 0.90 ʙ 0.92 ʢ100ˋʙ80ˋʣ 2 0.875 ʙ 0.889 ʢ100ˋʙ85ˋʣ 4 0.901 ʙ 0.920 ʢ100ˋʙ80ˋʣ ᴷ ɹɹɹɹ ᴷ

1.1 ʷ 0.25 2 0.97 ʙ 0.99 ʏ 4 1.00 ʙ 1.02 ʏ 2 0.975 ʙ 0.989 ʏ 4 1.001 ʙ 1.020 ʏ ᴷ ɹɹɹɹ ᴷ

1.2 ʷ 0.25 2 1.07 ʙ 1.09 ʏ 4 1.10 ʙ 1.12 ʏ 2 1.075 ʙ 1.089 ʏ 4 1.101 ʙ 1.120 ʏ ᴷ ɹɹɹɹ ᴷ

1.4 ʷ 0.3 2 1.244 ʙ 1.263 ʏ 4 1.270 ʙ 1.294 ʏ 2 1.245 ʙ 1.262 ʏ 4 1.270 ʙ 1.294 ʏ 4 1.270 ʙ 1.291 ʢ100ˋʙ82ˋʣ

1.6 ʷ 0.35 2 1.41 ʙ 1.44 ʢ100ˋʙ80ˋʣ 4 1.44 ʙ 1.48 ʢ100ˋʙ75ˋʣ 2 1.415 ʙ 1.442 ʢ100ˋʙ80ˋʣ 4 1.440 ʙ 1.466 ʢ100ˋʙ81ˋʣ 4 1.440 ʙ 1.475 ʢ100ˋʙ75ˋʣ

1.6 ʷ 0.2 ᴷ ᴷ ᴷ ᴷ ᴷ ᴷ ᴷ ᴷ 4 1.530 ʙ 1.550 ʢ100ˋʙ75ˋʣ

˞ɹ1.7 ʷ 0.35 ᴷ ɹɹɹɹ ᴷ 4 ˎ1.54 ʙ 1.58 ʏ ᴷ ɹɹɹɹ ᴷ ᴷ ɹɹɹɹ ᴷ ᴷ ɹɹɹɹ ᴷ

1.8 ʷ 0.35 2 1.61 ʙ 1.64 ʢ100ˋʙ80ˋʣ 4 1.64 ʙ 1.68 ʏ 2 1.615 ʙ 1.634 ʢ100ˋʙ86ˋʣ 4 1.640 ʙ 1.666 ʢ100ˋʙ81ˋʣ 4 1.640 ʙ 1.675 ʢ100ˋʙ75ˋʣ

2 ʷ 0.4 2 1.78 ʙ 1.82 ʏ 4 1.81 ʙ 1.85 ʏ 2 1.785 ʙ 1.806 ʏ 4 1.810 ʙ 1.840 ʏ 4 1.810 ʙ 1.849 ʏ

2 ʷ 0.25 2 1.88 ʙ 1.89 ʏ ᴷ ɹɹɹɹ ᴷ 2 1.875 ʙ 1.888 ʢ100ˋʙ87ˋʣ 4 1.901 ʙ 1.918 ʢ99ˋʙ82ˋʣ ᴷ ɹɹɹɹ ᴷ

2.2 ʷ 0.45 2 1.95 ʙ 1.99 ʏ 4 1.98 ʙ 2.03 ʢ100ˋʙ75ˋʣ 2 1.955 ʙ 1.979 ʢ100ˋʙ86ˋʣ 4 1.980 ʙ 2.012 ʢ100ˋʙ82ˋʣ 4 1.980 ʙ 2.024 ʢ100ˋʙ75ˋʣ

˞ɹ2.3 ʷ 0.4 ᴷ ɹɹɹɹ ᴷ 4 ˎ2.11 ʙ 2.15 ʏ ᴷ ɹɹɹɹ ᴷ ᴷ ɹɹɹɹ ᴷ ᴷ ɹɹɹɹ ᴷ

2.5 ʷ 0.45 2 2.25 ʙ 2.29 ʢ100ˋʙ80ˋʣ 4 2.28 ʙ 2.33 ʏ 2 2.255 ʙ 2.279 ʢ100ˋʙ86ˋʣ 4 2.280 ʙ 2.312 ʢ100ˋʙ82ˋʣ 4 2.280 ʙ 2.324 ʢ100ˋʙ75ˋʣ

˞ɹ2.6 ʷ 0.45 ᴷ ɹɹɹɹ ᴷ 4 ˎ2.38 ʙ 2.43 ʏ ᴷ ɹɹɹɹ ᴷ ᴷ ɹɹɹɹ ᴷ ᴷ ɹɹɹɹ ᴷ

˞ɹ3 ʷ 0.6 3 2.68 ʙ 2.70 ʢ100ˋʙ90ˋʣ 5 2.70 ʙ 2.73 ʢ100ˋʙ90ˋʣ ᴷ ɹɹɹɹ ᴷ ᴷ ɹɹɹɹ ᴷ ᴷ ɹɹɹɹ ᴷ

3 ʷ 0.5 3 2.74 ʙ 2.78 ʢ100ˋʙ80ˋʣ 5 2.76 ʙ 2.81 ʢ100ˋʙ75ˋʣ 3 2.737 ʙ 2.764 ʢ100ˋʙ86ˋʣ 5 2.762 ʙ 2.798 ʢ100ˋʙ82ˋʣ 5 2.762 ʙ 2.812 ʢ100ˋʙ75ˋʣ

3.5 ʷ 0.6 3 3.18 ʙ 3.21 ʢ100ˋʙ85ˋʣ 5 3.20 ʙ 3.26 ʏ 3 3.177 ʙ 3.210 ʏ 5 3.202 ʙ 3.242 ʢ100ˋʙ83ˋʣ 5 3.202 ʙ 3.250 ʢ100ˋʙ80ˋʣ

˞ɹ4 ʷ 0.75 4 3.60 ʙ 3.64 ʏ 6 3.62 ʙ 3.67 ʢ100ˋʙ85ˋʣ ᴷ ɹɹɹɹ ᴷ ᴷ ɹɹɹɹ ᴷ ᴷ ɹɹɹɹ ᴷ

4 ʷ 0.7 4 3.63 ʙ 3.67 ʏ 6 3.65 ʙ 3.70 ʏ 4 3.63 ʙ 3.66 ʢ100ˋʙ88ˋʣ 4 3.63 ʙ 3.67 ʢ100ˋʙ85ˋʣ 6 3.66 ʙ 3.69 ʢ100ˋʙ85ˋʣ

4.5 ʷ 0.75 4 4.10 ʙ 4.14 ʏ 6 4.12 ʙ 4.18 ʢ100ˋʙ80ˋʣ 4 4.10 ʙ 4.13 ʏ 4 4.10 ʙ 4.14 ʏ 6 4.13 ʙ 4.18 ʢ100ˋʙ80ˋʣ

˞ɹ5 ʷ 0.9 4 4.51 ʙ 4.56 ʏ 6 4.53 ʙ 4.59 ʢ100ˋʙ85ˋʣ ᴷ ɹɹɹɹ ᴷ ᴷ ɹɹɹɹ ᴷ ᴷ ɹɹɹɹ ᴷ

5 ʷ 0.8 4 4.57 ʙ 4.62 ʏ 6 4.59 ʙ 4.66 ʢ100ˋʙ80ˋʣ 4 4.57 ʙ 4.60 ʢ100ˋʙ88ˋʣ 4 4.57 ʙ 4.61 ʢ100ˋʙ85ˋʣ 6 4.60 ʙ 4.65 ʢ100ˋʙ80ˋʣ

6 ʷ 1 4 5.45 ʙ 5.51 ʏ 7 5.48 ʙ 5.57 ʏ 4 5.45 ʙ 5.49 ʏ 4 5.45 ʙ 5.50 ʏ 7 5.49 ʙ 5.56 ʏ

7 ʷ 1 4 6.45 ʙ 6.51 ʏ 7 6.48 ʙ 6.57 ʏ 4 6.45 ʙ 6.49 ʢ100ˋʙ89ˋʣ 4 6.45 ʙ 6.50 ʏ 7 6.49 ʙ 6.56 ʏ

8 ʷ 1.25 5 7.31 ʙ 7.38 ʏ 7 7.34 ʙ 7.41 ʢ100ˋʙ85ˋʣ 5 7.31 ʙ 7.36 ʢ100ˋʙ90ˋʣ 7 7.34 ʙ 7.40 ʢ100ˋʙ87ˋʣ 7 7.34 ʙ 7.41 ʢ100ˋʙ85ˋʣ

8 ʷ 1 4 7.45 ʙ 7.51 ʏ 7 7.48 ʙ 7.57 ʢ100ˋʙ80ˋʣ 4 7.45 ʙ 7.48 ʢ100ˋʙ91ˋʣ 4 7.45 ʙ 7.50 ʢ100ˋʙ85ˋʣ 7 7.49 ʙ 7.56 ʢ100ˋʙ80ˋʣ

10 ʷ 1.5 5 9.16 ʙ 9.22 ʢ100ˋʙ90ˋʣ 7 9.18 ʙ 9.28 ʢ100ˋʙ85ˋʣ 5 9.16 ʙ 9.21 ʏ 7 9.19 ʙ 9.24 ʢ100ˋʙ90ˋʣ 7 9.19 ʙ 9.27 ʢ100ˋʙ85ˋʣ

10 ʷ 1.25 5 9.31 ʙ 9.38 ʢ100ˋʙ85ˋʣ 7 9.34 ʙ 9.41 ʏ 5 9.31 ʙ 9.36 ʢ100ˋʙ90ˋʣ 7 9.34 ʙ 9.40 ʢ100ˋʙ87ˋʣ 7 9.34 ʙ 9.41 ʏ

10 ʷ 1 5 9.46 ʙ 9.52 ʏ 7 9.48 ʙ 9.57 ʢ100ˋʙ80ˋʣ 5 9.47 ʙ 9.50 ʏ 5 9.47 ʙ 9.52 ʢ100ˋʙ85ˋʣ 7 9.49 ʙ 9.56 ʢ100ˋʙ80ˋʣ

12 ʷ 1.75 5 11.01 ʙ 11.08 ʢ100ˋʙ90ˋʣ 8 11.05 ʙ 11.15 ʢ100ˋʙ85ˋʣ 5 11.01 ʙ 11.07 ʢ100ˋʙ91ˋʣ 8 11.05 ʙ 11.11 ʢ100ˋʙ90ˋʣ 8 11.05 ʙ 11.15 ʢ100ˋʙ85ˋʣ

12 ʷ 1.5 5 11.16 ʙ 11.22 ʏ 7 11.18 ʙ 11.28 ʏ 5 11.16 ʙ 11.21 ʏ 7 11.19 ʙ 11.24 ʏ 7 11.19 ʙ 11.27 ʏ

12 ʷ 1.25 5 11.31 ʙ 11.38 ʢ100ˋʙ85ˋʣ 7 11.34 ʙ 11.41 ʏ 5 11.31 ʙ 11.36 ʢ100ˋʙ90ˋʣ 7 11.34 ʙ 11.40 ʢ100ˋʙ87ˋʣ 7 11.34 ʙ 11.41 ʏ

12 ʷ 1 5 11.46 ʙ 11.52 ʏ 7 11.48 ʙ 11.57 ʢ100ˋʙ80ˋʣ 5 11.47 ʙ 11.50 ʏ 5 11.47 ʙ 11.52 ʢ100ˋʙ85ˋʣ 7 11.49 ʙ 11.56 ʢ100ˋʙ80ˋʣ

14 ʷ 2 6 12.83 ʙ 12.95 ʢ100ˋʙ90ˋʣ 10 12.92 ʙ 13.04 ʢ100ˋʙ85ˋʣ 6 12.88 ʙ 12.93 ʢ100ˋʙ92ˋʣ 10 12.93 ʙ 13.00 ʢ100ˋʙ90ˋʣ 10 12.93 ʙ 13.04 ʢ100ˋʙ85ˋʣ

14 ʷ 1.5 5 13.16 ʙ 13.22 ʏ 9 13.21 ʙ 13.30 ʏ 5 13.16 ʙ 13.21 ʢ100ˋʙ91ˋʣ 9 13.21 ʙ 13.27 ʏ 9 13.21 ʙ 13.30 ʏ

16 ʷ 2 6 14.87 ʙ 14.95 ʏ 10 14.92 ʙ 15.04 ʏ 6 14.88 ʙ 14.93 ʢ100ˋʙ92ˋʣ 6 14.88 ʙ 14.95 ʏ 10 14.93 ʙ 15.04 ʏ

16 ʷ 1.5 5 15.16 ʙ 15.22 ʏ 9 15.21 ʙ 15.30 ʢ100ˋʙ80ˋʣ 5 15.16 ʙ 15.21 ʢ100ˋʙ91ˋʣ 9 15.21 ʙ 15.27 ʏ 9 15.21 ʙ 15.30 ʏ

18 ʷ 2.5 6 16.57 ʙ 16.67 ʏ 11 16.63 ʙ 16.78 ʢ100ˋʙ85ˋʣ 6 16.57 ʙ 16.64 ʢ100ˋʙ92ˋʣ 11 16.64 ʙ 16.73 ʏ 11 16.64 ʙ 16.78 ʏ

18 ʷ 1.5 6 17.17 ʙ 17.23 ʏ 10 17.22 ʙ 17.31 ʏ 6 17.18 ʙ 17.22 ʢ100ˋʙ91ˋʣ 6 17.18 ʙ 17.23 ʏ 10 17.23 ʙ 17.31 ʏ

20 ʷ 2.5 6 18.57 ʙ 18.67 ʏ 11 18.63 ʙ 18.78 ʏ 6 18.57 ʙ 18.64 ʢ100ˋʙ92ˋʣ 11 18.64 ʙ 18.73 ʏ 11 18.64 ʙ 18.78 ʏ

20 ʷ 1.5 6 19.17 ʙ 19.23 ʏ 10 19.22 ʙ 19.31 ʏ 6 19.18 ʙ 19.22 ʢ100ˋʙ91ˋʣ 6 19.18 ʙ 19.23 ʏ 10 19.23 ʙ 19.31 ʏ

22 ʷ 2.5 ᴷ ᴷ 11 20.63 ʙ 20.78 ʢ100ˋʙ85ˋʣ ᴷ ᴷ ᴷ ᴷ 11 20.63 ʙ 20.78 ʢ100ˋʙ85ˋʣ

22 ʷ 1.5 ᴷ ᴷ 10 21.22 ʙ 21.31 ʏ ᴷ ᴷ ᴷ ᴷ 10 21.22 ʙ 21.31 ʏ

24 ʷ 3 ᴷ ᴷ 13 22.36 ʙ 22.53 ʏ ᴷ ᴷ ᴷ ᴷ 13 22.36 ʙ 22.53 ʏ

24 ʷ 1.5 ᴷ ᴷ 10 23.22 ʙ 23.31 ʏ ᴷ ᴷ ᴷ ᴷ 10 23.22 ʙ 23.31 ʏ

27 ʷ 3 ᴷ ᴷ 13 25.36 ʙ 25.53 ʏ ᴷ ᴷ ᴷ ᴷ 13 25.36 ʙ 25.53 ʏ

30 ʷ 3.5 ᴷ ᴷ 14 28.07 ʙ 28.25 ʏ ᴷ ᴷ ᴷ ᴷ 14 28.07 ʙ 28.25 ʏ

33 ʷ 3.5 ᴷ ᴷ 14 31.07 ʙ 31.25 ʏ ᴷ ᴷ ᴷ ᴷ 14 31.07 ʙ 31.25 ʏ

36 ʷ 4 ᴷ ᴷ 15 33.78 ʙ 33.99 ʏ ᴷ ᴷ ᴷ ᴷ 15 33.78 ʙ 33.99 ʏ

42 ʷ 4.5 ᴷ ᴷ 16 39.49 ʙ 39.71 ʏ ᴷ ᴷ ᴷ ᴷ 16 39.49 ʙ 39.71 ʏ

45 ʷ 4.5 ᴷ ᴷ 16 42.49 ʙ 42.71 ʏ ᴷ ᴷ ᴷ ᴷ 16 42.49 ʙ 42.71 ʏ

)ʙ )+*4 # ʹΑΔɻ 4H - 6H corresponds to JIS B 0209-2001.

ฒαΠζ+*4 # ଐॻ ʹΑΔɻ Coarse thread sizes correspond to the appendix 1 of JIS B 0209-1982.

ࡉαΠζ+*4 # ଐॻʹΑΔɻ Fine pitch thread sizes correspond to the appendix of JIS B 0211-1982.

ˎҹ+*4 # ଐॻ ʹΑΔɻ ˎCorresponds to the appendix 2 of JIS B 0209-1982.

˞ҹ+*4ഇࢭαΠζͰ͢ɻ ˞Size abolished by JIS.

1. ্දͷԼ݀ܘɺඃࡐʹΑΓҟͳΓ·͢ͷͰɺ҆ͱͯ͠Լ͍͞ɻ 1. The proper drill hole size may change due to material variety. Use the

2. Լ݀ܘඃࡐɾߗ͞ɾܗঢ়ੇ๏ʹΑΓ্͕Γੑ͕ଟগมΘΓ·͢ͷͰ recommended drill hole size as a benchmark.

ࢼ͠Ճͷ্ܾఆԼ͍͞ɻ 2. As the hole diameter may vary by behavior of plasticity depending

on the material, hardness and shapes of workpiece, the hole diameter

3. ٱੑΛߟྀ͢ΔͱɺԼ݀ܘେ͖Ίͷํ͕༗རͰ͢ɻతʹ߹ΘͤͯબఆԼ͍͞ɻ should be determined through trial tapping prior to f nal machining.

4. Լ݀ۂ͕Γɺ͏ͶΓɺ৺ͣΕ͕͋ΔͱɺτϥϒϧͷݪҼʹͳΓ·͢ͷͰ͝ҙԼ͍͞ɻ 3. A larger drill hole size is better for extending tool life. Select a drill hole

size based on your particular application.

4. To avoid tapping trouble, correct hole must be maintained free from

warp, deformation, stagger and the like.

G-17